Reflections from 37+ years of Resource Procurement and Management

I have always loved sport analogies to drive alignment around business strategies. In my 37 years in this amazing industry, I’ve seen that the use of a relevant sports analogy can be critical to helping others gain understanding of a topic they’ve either not given much thought to or have shrugged their shoulders and ignored as it may be outside of their expertise or beyond their span of control.

With that preamble, I’ll share that sawmilling is like a relay race. Winning teams end up on the podium because every member of their team executes their role perfectly, and they are able to handoff to their teammate in a way that doesn’t slow them down or hold them back.

In sawmilling, the relay starts with the Resources department getting the right log, to the right mill, at the right time, for the right price. From there, the baton transitions to mill Operations, who must convert that log to the highest value products, with the maximum possible recovery, at the lowest converting cost. Those that end up on the podium in both good years and bad have mastered these two legs of the race. They are the companies that maximize profitability in all market conditions by managing the core profit drivers at each leg of the relay, ensuring tight coordination and communication between the legs. In short, winners work by optimizing the whole team, while those left off the podium all too often run each leg of the relay as an independent race… as if no coordination or inter-dependent optimization of the whole is required.

As I reflect on my long career, I can state with confidence what my extensive history has taught me: It is almost impossible for mill operations to recover from poor resource decisions.

This is the first article in a two-part series on this relay race we call Sawmilling and will focus on Resource Procurement. In a subsequent article I’ll head inside the mill fence to focus on mill operations.

MAXIMIZING PROFITABILITY MEANS DELIVERING THE RIGHT LOG, TO THE RIGHT MILL, AT THE RIGHT TIME, AT THE RIGHT PRICE

Sounds great, doesn’t it? Catchy little phrase, but it’s much harder than it looks.

Let me tell you how incredibly hard it is…

The challenges faced by Resource departments can look very different based on the size, location, and integration of their company. Three common log procurement challenges that I have personally experienced in my career are:

- Small mills on the open market competing with juggernauts in a very tight log market.

- An operation heavily dependent on USFS volume (or lack thereof…)

- A mill that is part of a vertically integrated corporation dealing with log allocation from the Timberlands Division to the Mill Division

While I recently stepped down as CEO from a wonderful family company with several sawmills (Neiman Enterprises), I began my career cruising timber on the Oregon coast in the early 1980’s. My first taste for log buying came in 1987 as a District Forester for a family company (P&M) that had 5 sawmills and no fee timber. Smart, strong appraisals were critical to our success. I learned the value of tight timber cruises, and meaningful and accurate return-to-log (RTL) studies to drive profitability. I advanced to the position of Director of Resources rather quickly using a data driven approach to business decisions. After 13 years scrapping in the open market for logs, I had the privilege to be the California Operations Manager for Roseburg Forest Products (RFP) over 320,000 acres of fee timber, and milling operations. It is here with both milling and resource operations I learned the “true value” of integrated profitability and stepping out of silo profitability within individual businesses to drive maximum achievable profitability. After a dozen years with RFP it was on to a large publicly traded company, PotlatchDeltic. When I left after a decade, I was the Regional Manufacturing Manager over 4 milling operations. With PotlatchDeltic the resource and manufacturing interaction and optimization was achieved at even higher levels. Detailed and optimized RTL’s drove capital upgrade decisions through smart procurement and fee utilization and interactions.

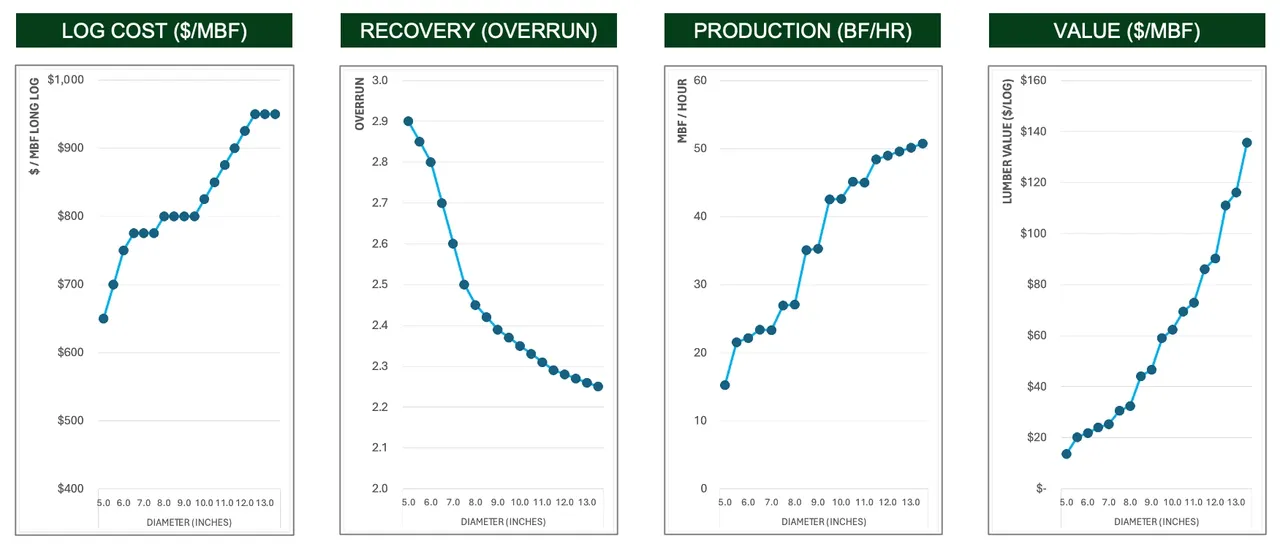

Figure 1: A proper RTL model for your mill operations must take into consideration the full impact on all the financial drivers based on log characteristics (species, quality, diameter, etc.).

Throughout my career, my passion has always been delivering the log that will allow the mill to excel and achieve maximum profitability. That means knowing the mill performance opportunities on an optimized log mix. I am a firm believer that the resource procurement area is the most under-supported area within the “supply chain” in the timber industry. Smart procurement requires many tools in the toolbox, deep smart business analysis, and strong resource-to-mill interactions to be successful.

OSORNO: HELPING FOREST PRODUCTS COMPANIES REACH THEIR FULL POTENTIAL

That is why I am happy to have joined Osorno in 2024 as a Senior Advisor. Osorno is a consulting company that is already well known for verifiable in-mill improvements to Value, Recovery, Maintenance and Reliability. This year I have joined Osorno to help expand its offerings to include helping clients with resources procurement. I am leveraging several decades of experience and battle scars to support bringing this valuable addition to the timber industry. Osorno’s new Resource offering links specific tools, processes, and proven analytics to inbound log resources to provide the best opportunity for a mill to be successful on an extended basis in highly competitive working circles.

The resource area is dynamic, challenging, ever changing, and requires the highest level of business savvy using the best tools and platforms to be consistently excellent in maximizing operational profitability. I am confident that our Osorno Resource offering will be a game changer to the bottom line of Osorno clients.

If your organization would like to improve your log procurement practices in the face of a very challenging lumber market, we can help.

STAY TUNED…

This has been the first in a two-part series on this relay race we call Sawmilling. In my next article I’ll head inside the mill fence to focus on mill operations.

NEED HELP, OR WANT TO DISCUSS FURTHER?

Our focus is on helping forest products companies identify and capture the millions of dollars a year that can be lost in each mill through sub-optimal execution.

With more than 20 years of successful experience helping dozens of companies in 15 countries across 3 continents, we can help you too.