Would your Optimizer call you “Predictable”?

Over the years lumber companies have wisely invested heavily in optimization as a way to remove human error and influence from log/cant/board breakdown decisions. This technology, so the sales pitch goes, allows a computer to leverage all available data (log diameter, shape, taper, defects, green lumber sizes, wane allowances, saw kerf, pricing, etc) to ALWAYS make the “RIGHT” decision in the blink of an eye, and in so doing truly “Optimize” the log in a way that simply wasn’t possible before. Mills everywhere have installed these systems from multiple suppliers, and each machine represents a truly amazing potential benefit to the mill…a potential that nearly every lumber mill fails to fully realize because of two reasons.

1. An improper optimization strategy; and

2. Poor execution of the optimized solution…aka poor PREDICTABILITY.

Our recent blog post titled “T-Bones or 2x4s?” launched our series on lumber manufacturing by first recognizing that unlike most other kinds of manufacturing, lumber is considered a “DECONSTRUCTIVE” manufacturing process. One where the maximum value that the lumber mill can hope to get out of the tree stem is defined by how perfectly they deconstruct the tree. EVERY DECISION…EVERY CUT…is critical to the company making the most money it can. If you missed that article, I invite you to go back and give it a read. Understanding how deconstructive manufacturing differs from all other forms of manufacturing is critical to understanding this series going forward. You can check out that article here.

It is with the realities of deconstructive manufacturing in mind that the two reasons for unrealized benefit I identified above should be alarming:

1. An improper optimization strategy affects EVERY DECISION.

2. Poor execution of the optimized solution (poor Predictability) can play out in EVERY CUT.

In our experience, these two issues result in the loss of millions of dollars per mill…per year!

We’re going to take this topic and split it into two articles. This article is going to focus on Predictability, as it is the necessary precursor to effectively implementing the right strategy. In a future article we’ll tackle what to consider in defining the right optimization strategy.

THE CONCEPT

When I discuss topics, I always like to invoke visuals that my audience can readily understand. Having worked 20+ years around the forest products industry, I’ve learned that certain analogies work really well, and others don’t. An analogy involving Nascar, College Football, or hunting & shooting tends to be met with knowing nods and a quick understanding of the concept. Once the concept is understood, applying the learning becomes easier because it just makes sense.

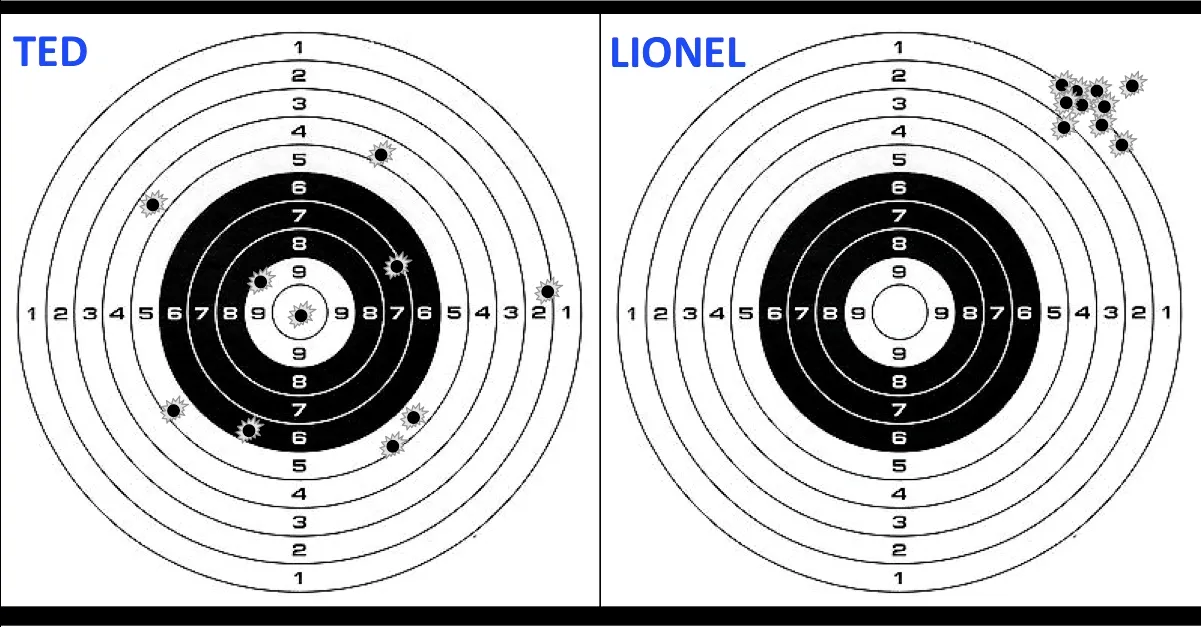

Below are illustrations of two rifle targets from Ted and Lionel as they sighted in their deer rifles before hunting season. In looking at the two targets, you’ll see that Ted got two solid hits in the bullseye, one in the 7-ring, one in the 6-ring and the others in the 5-ring and below. Lionel, on the other hand, got all of his hits in the top-right in the 2- and 1-ring, and even a few outside of the target.

So the question is this: Who is the better shooter?

Anyone who knows anything about shooting would immediately identify LIONEL as the better shooter. Though he was way outside of the bullseye, he EXECUTED CONSISTENCY in his shooting. The grouping of his ten shots was so tight that all he needs to do is adjust his scope (LEFT, DOWN) and he can get nearly every shot in the bullseye. For Ted to improve upon the two bullseyes he got, there’s nothing simple for him to do…no scope adjustment he can make. His shots are all over the place, and likely are being caused by a number of issues: breathing, trigger control, anticipating recoil, poor focus on the crosshairs, loose scope mounts, etc, etc. With so many issues at play, he can’t go fumbling with his scope…he needs to focus on fundamentals and execution.

Similarly, before altering an optimization strategy, lumber mills must first know and understand their PREDICTABILTY. Once a mill is able to consistently demonstrate high levels of Predictability, then implementation of a revised optimization strategy works like the flipping of a switch (akin to adjusting Lionel’s scope…) in delivering immediate financial improvement.

Below I’ve laid out a 4-step approach to integrating Predictability into your operations.

STEP 1: DEFINE PREDICTABILITY CONSISTENTLY ACROSS YOUR ORGANIZATION

Lumber mill Predictability should be defined as the level of accuracy of the actual lumber mix in the green sorter versus the anticipated lumber mix that was optimized at the primary breakdown on a piece-by-piece, dimension/length basis.

Having been in a lot of mills, I’ve discussed Predictability with a lot of people whose understanding of this concept typically falls into one of two camps. “What are you talking about?” or “We kind of track that…” This second camp often compares “total BF” in the green sorter vs. anticipated BF at the primary breakdown…or “total lumber value”…or even “total pieces”. While appearing to be helpful, all of these things are counterproductive as they can give a false sense that your process is under control. True Predictability means that when your primary breakdown optimizer sets saws to wood to get a 12ft 2×10, that’s what you actually get. Under the “total BF” pseudo-Predictability, I’ve seen people feeling good that their intended 12ft 2×10 ended up as a 16ft 2×8 because they “gained BF”.

STEP 2: ELEVATE PREDICTABILITY TO A WEEKLY KPI

If you’re responsible for optimization in a lumber mill, or you’re a mill manager, a VP Manufacturing, or CEO, you should be able to look at your company’s weekly management report and see a PREDICTABILITY KPI that you and your team focus on with rigor.

If you don’t have that KPI in place, you have a major blind spot akin to Ted and Lionel sighting in their rifles by shooting at a target that’s behind a curtain. Both might tell themselves “that felt pretty good”, or “I feel like I’m shooting consistently”, but they really have no idea if they need to improve, or what they should do. Without a Predictability KPI, you and your team may be “feeling good” that you’re likely “shooting consistently”…but you don’t know, and that should bother you.

STEP 3: ADDRESS ROOT CAUSE ISSUES

The first time a mill runs a test to measure their Predictability, the results are often quite poor, and it is never a simple fix to get it right. Improving, and maintaining high levels of Predictability is a constant process of Root Cause Analysis (RCA), and your team needs to be up to the challenge. The most effective, but not the only tool I’ve found for RCA of Predictability is the Fishbone Diagram using the “5 Ms”.

- Machine

- Method

- Material

- Man

- Measurement

This tool is excellent at getting a team to compartmentalize poor Predictability into one, or multiple causes, and from there to identify root causes and address them through highly specific and targeted action plans and/or maintenance work requests.

STEP 4: GO BACK TO STEP 2 AND REPEAT…

Once you’ve achieved a high degree of Predictability, you should feel great about it, but realize that things can get un-Predictable very quickly. Scanners get covered in sawdust… a night shift supervisor makes a “temporary adjustment” to the optimizer and doesn’t report it…heavy logs smash into things and slop is introduced into a machine center…etc.

You can’t think about Predictability as a short-term thing to check and “get right” and then forget about it and “get back to work”. That’s like dieting to lose weight, then going back to the way you used to eat and expecting to stay thin. Predictability must be an integral way to manage a lumber mill… not just a “fad diet”.

THE BIG “WHY”

Predictability, put simply, is doing what you intended to do. If you’re going to keep on intending to do the same thing (no change in your optimization strategy), then high Predictability means you’re better off because you’re consistently delivering on your confirmed objective.

If, however, you’re willing to consider a change to your optimization strategy, then having high Predictability is the critical precursor to confidently “flipping the switch” on a strategy that can deliver dramatically improved financial results.

STAY TUNED…

This is just the 2nd article in our series on lumber manufacturing. In the coming weeks and months we will be continuing with thought provoking articles on all aspects of the business. Look for upcoming articles on Optimization Strategy, Kiln Drying, Timber Procurement, Production, Maintenance, Leadership, and more.

NEED HELP, OR WANT TO DISCUSS FURTHER?

Our focus is on helping forest products companies identify, and capture the millions of dollars a year that can be lost in each mill through sub-optimal execution.

With more than 20 years of successful experience helping dozens of companies in 15 countries across 3 continents, we can help you too.

Check out our services, and drop us a line. Let’s start a conversation.

HELP US SPREAD THE WORD

If you liked this article, please pass along to your friends by sharing a link to the blog, or sharing this page on LinkedIn or Facebook.

Stay sharp.